Optical Circuit Switches in AI Hyperscale Data Centers – The MEMS Advantage

11/19/2025

Optical circuit switching (OCS) is drawing intense interest when it comes to improving data center networking (DCN) in AI hyperscale environments, where efficient workload processing hinges upon massive parallelism, real-time data movement, and ultra-low latency networking. OCS was a leading topic of conversation at the recent ECOC Conference and Exhibition where we announced our new OCS R64 platform, the second member of the OCS family after the R300 which we introduced earlier this year at OFC in San Francisco.

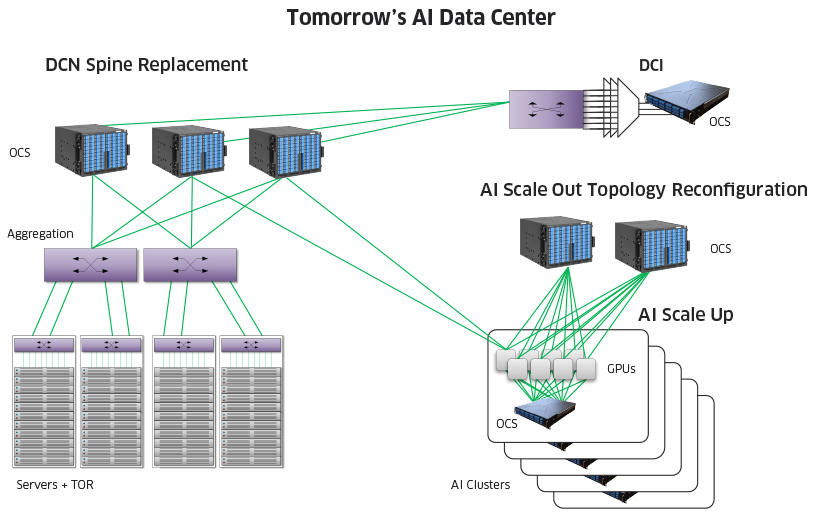

OCS is seen as a replacement for traditional packet-based switching fabrics, such as DCN spine switches, which act as a central backbone connecting all leaf switches, which in turn connect to servers and storage. Replacing spine switches with an OCS would reduce significantly both power consumption and networking latency, which are top requirements to address the scale and performance demands of AI and ML workloads.

We recently presented our views at an OCS webinar hosted by the industry analyst firm Cignal AI. The webinar focused on AI scaling and data center automation / increased efficiency and covered how technologies such as MEMS, silicon photonics, robotic fiber switching and digital liquid crystal can reduce operational complexity, increase speeds, lower power consumption and enable larger networks.

A frank discussion also took place on the ongoing deployment challenges in various environments and the market trajectory for these applications. One can conclude from this webinar that this sector is growing and evolving rapidly and that well-funded technology platforms have a chance of gaining significant market share. What follows is a closer examination of a MEMS-based OCS and its benefits in terms of scalability, latency reduction, and energy efficiency in hyperscale data center applications.

A MEMS OCS features an array of tiny movable mirrors embedded on a silicon substrate to direct optical signals between input and output fibers. Each input port corresponds to an optical fiber carrying high-capacity wavelength channels and each output port connects to another fiber leading to a computing node or another switch. This is part of the “all optical” model that reduces power consumption and latency as the signal is not converted into the electrical domain, as is the case with conventional packet / spine switches.

As a result, the R300 has demonstrated 98% reduction in switch latency vs. an OEO packet switch solution. Furthermore, our 3D-MEMS architecture incorporates mirrors that tilt continuously along two axes, allowing precise alignment of any input beam to any output fiber across a large free-space switching fabric. Our single-crystal silicon MEMS design also eliminates “hinge fatigue” and enables hundreds of millions of operational cycles with no failures.

This capability is embodied in the R300, which currently supports up to 300x300 ports with a typical insertion loss of 1.5 dB or less. Furthermore, the high switch radix of the R300 enables a flat network architecture that can scale to support the massive numbers of GPUs (100,000+) needed for hyperscale AI deployments. And a note about the importance of low-loss performance –this is a critical feature, as it is one of the key technical hurdles to the introduction of OCS technology into hyperscale environments. This is seen in the requirement to support additional OCS loss within transceiver link budgets – around 4dB for FR4/DR4 and 6dB for LR4/ER4.

For MEMS systems in general, the control plane is instrumental in establishing a circuit by computing the required tilt angles and activating the mirrors accordingly. Once set, the optical path remains stable and creates a dedicated, high-bandwidth channel until the configuration is changed.

The control software for the R300 is based on the popular, open-source SONiC OS and augments our proprietary MEMS design, which does not need a “closed loop” control mechanism. SONiC is also beneficial, in terms of “seamless integration,” in that it provides an interface to integrate the OCS into existing datacenter network level control planes.

Operating costs are reduced further via the R300’s ultra-wideband capability, i.e., seamless access across the O-, C- and L-bands and its bit-rate transparency. In fact, the “bit rate” element is another key advantage of MEMS systems, as a MEMS OCS does not impose a bandwidth limit beyond the optical fiber itself. Whether the link operates at 400 Gbps, 800 Gbps, or future 1.6 Tbps line rates, the switch remains protocol- and rate-transparent. This makes it inherently future-proof and capable of scaling with next-generation optical transceivers.

Closing Thoughts and Next Steps

Training large AI models involves hundreds or thousands of graphical processing units (GPUs) or tensor processing units (TPUs) working in tightly coupled clusters. These accelerators require rapid exchange of data, gradient updates, and parameter synchronization. The resulting east-west traffic patterns within the data center are characterized by high volume, burstiness, and the need for low-latency communication.

Traditional electronic packet switches are now struggling to handle these traffic demands, as they can suffer from buffering and queuing delays and the power consumption factor makes large fabrics unsustainable.

A MEMS-based OCS, on the other hand, complements or overlays the packet-switched network by providing direct, reconfigurable optical paths between clusters of compute nodes. For example, the OCS can dynamically create dedicated optical circuits interconnecting the hundreds of GPU nodes assigned to a large training job. This eliminates intermediate hops through multiple electronic switches, significantly reducing both latency and congestion. Additionally, with the new AI training applications being implemented, the traffic is generally considered to be very predictable, which is beneficial for OCS.

As for power consumption, unlike electronic switches that consume power continuously in processing and forwarding packets, a MEMS switch consumes energy primarily during reconfiguration of mirrors. Once set, the mirrors hold their position with minimal static power draw. This leads to orders-of-magnitude lower energy consumption per switched bit.

Looking down the road, opportunities for future OCS evolution include the implementation of multi-hop optical switching, faster switching – from the milliseconds of today to the microseconds for optical burst switching, and very high radix fabrics, as 3D MEMS switches can scale to very large port counts (e.g., 1024×1024 or beyond) in a compact footprint.

For more information, visit our Optical Circuit Switches page.